From Types to Applications | Learn Everything About Mild Steel Pipe and Tube

When it comes to sourcing MS tube Baghdad, Iraq, it is immensely appreciated in the market as a noteworthy stainless mild steel pipe and tube manufacturer, exporter, dealer, trader, and wholesale supplier of a complete range of stainless steel pipes. Mild Steel pipes and tubes are one of the most widely used types of steel pipes and tubes worldwide. It has also become very popular in the construction and infrastructure industry because of its competitive price range, ease of use, physical attributes, sustainability, and versatility, including ductility and malleability. It is also known for having a low carbon content of about 0.05% to 0.30%.

At Matco Industry, we manufacture our extensive mild steel pipe in Mosul, Iraq, following the guidelines of ASME/ASTM and many other international standards. We are pleased to offer our pipes and tubes range to our reliable clients and consumers based in Iraq. However, in this comprehensive blog, we will discuss the key pointers that will provide end-to-end information about mild steel pipes and tubes. Whether you want to know about the key types, features, pros, cons, and more, you will get all the precise details in this blog. Let’s get started!

Technical Configuration of Mild Steel Pipe and Tube

| Parameter | Specifications |

|---|---|

| Product Types | MS ERW (Electric Resistance Welded) Pipes, MS Seamless Pipes, MS Black Pipes |

| Grades (Common) | IS 1239 (Part 1), ASTM A53 Grade A/B, BS 1387, EN 10255 |

| Standard Sizes (OD) | 15 mm (1/2″) to 300 mm (12″) |

| Wall Thickness (WT) | 1.5 mm to 12 mm |

| Length | 6 meters (standard), or as per customer requirement (up to 12m for containers) |

| Shape | Round, Square, Rectangular |

| Surface Finish | Black (self-colored), Galvanized (GI coated), Varnished (anti-rust) |

| End Finish | Plain Ends / Beveled Ends / Threaded with Couplings |

| Manufacturing Technique | ERW (Electric Resistance Welded), Seamless (for high-pressure use) |

| Tolerance | As per IS/ASTM standards, generally ±10% on thickness |

| Weight | As per IS 1239 or IS 3589 standards (varies with size and thickness) |

| Test Certification | Mill Test Certificate (MTC), Hydrostatic Pressure Test, Third-party inspection |

| Usage/Application | Water and gas transportation, structural applications, scaffolding, fencing |

| Coating Options | Oil-coated, Epoxy Coated, 3LPE Coated (for underground pipelines) |

| Packing | Bundled with steel straps, plastic-wrapped ends. Export packaging on request |

| Export Compliance | CE Marking (for EU compliance), ISO 9001:2015, Iraqi Quality Mark (optional) |

Popular Mild Steel Pipes and Tubes Sizes in Demand (Round Pipes)

| OD (mm) | Thickness (mm) | Weight (Kg/m) | Standard Use |

|---|---|---|---|

| 25.4 | 2 | 1.43 | Fencing, water lines |

| 48.3 | 3.2 | 3.67 | Scaffolding, construction |

| 76.1 | 4 | 7.2 | Water/Gas pipelines, structure |

| 114.3 | 5 | 13.6 | Industrial pipelines |

| 168.3 | 6 | 24.7 | High-flow lines, pressure systems |

What are the Types of Mild Steel Pipe and Tube?

Check out the two primary types of MS pipe in Basra, Iraq, that you must know before purchasing it for your project.

1. Galvanized Iron (GI) Pipes and Tubes

The addition of a thick layer of zinc coating characterizes it. Therefore, galvanized iron pipes are also known for their corrosion resistance qualities.

Technical Configuration of Galvanized Iron Pipes and Tubes

| Parameter | Details |

|---|---|

| Material | Mild Steel (MS), hot-dip galvanized for corrosion resistance |

| Coating | Zinc coating (Hot Dip Galvanized) — 210–550 g/m² |

| Standard Specification | IS:1239 (Part 1) – 2004; IS:3589; ASTM A53 / A120 |

| Sizes Available (Nominal Bore) | 20 mm (¾”), 25 mm (1”), 32 mm (1¼”), 40 mm (1½”), 50 mm (2”), up |

| Wall Thickness (B-Class) | 2.65 mm to 4.85 mm depending on size |

| Length of Pipe | Standard 6 meters (can vary on request) |

| Threading | BSPT (British Standard Pipe Tapered), male/female threaded ends or plain |

| Tensile Strength | ≥ 320 MPa |

| Yield Strength | ≥ 195 MPa |

| Elongation | ≥ 20% on 5.65 √A gauge length |

| Zinc Coating Thickness | 40–70 microns typically (varies by standard) |

| Working Pressure | Varies by class (Light, Medium, Heavy); e.g., 7 to 25 kg/cm² |

| End Finish | Plain, Threaded, or Socketed |

| Color Code (as per IS 1239) | Light Class: Blue; Medium Class: Yellow; Heavy Class: Red |

| Corrosion Resistance | High — due to zinc protection |

| Applications | Plumbing, Firefighting systems, Irrigation, Water & Gas pipelines, Fencing |

| Joining Method | Socket Joint, Threaded Joint, Welding (rare) |

The Usage of Galvanized Iron Pipe in Iraq

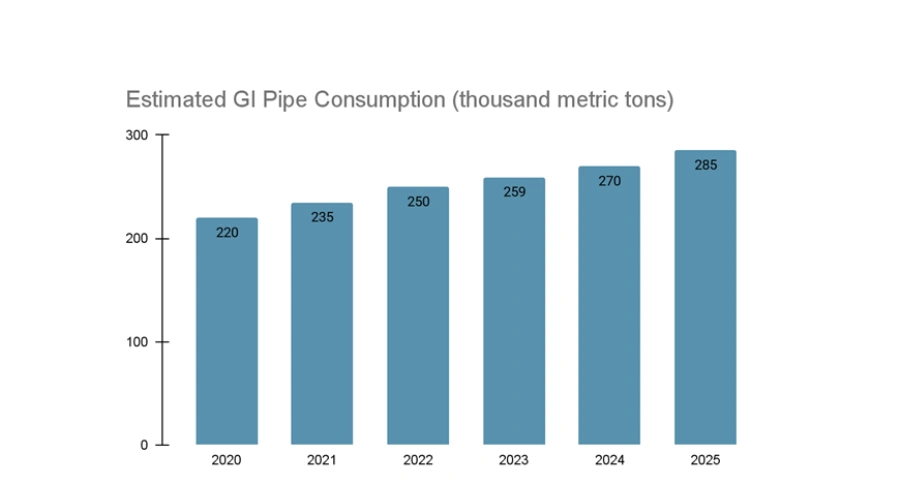

Here, in this bar graph, we have mentioned the usage of GI pipes between 2020 and 2025.

2. Non-Galvanized Mild Steel Pipes

MS Black Pipes are a common name for mild steel pipes and tubes that are not galvanized. Similarly, unlike galvanized iron pipes, these pipes and tubes lack a thick layer of zinc coating.

Technical Configuration of Non-Galvanized Iron Pipes

| Parameter | Specification |

|---|---|

| Material | Mild Steel (MS) or Carbon Steel |

| Surface Finish | Black (uncoated), mill finish, or light oil-coated to prevent temporary rusting |

| Manufacturing Standard | IS 1239 (Part 1) / IS 3589 / ASTM A53 / ASTM A106 / API 5L (for large-diameter) |

| Pipe Type | Seamless or ERW (Electric Resistance Welded) |

| Outer Diameter Range | 15 mm to 600 mm (½ inch to 24 inches nominal bore) |

| Wall Thickness (SCH) | SCH 10, SCH 20, SCH 40, SCH 80, etc. (varies by application and pressure class) |

| Length | 6 meters (standard), or custom as per requirement |

| End Connections | Plain End (PE), Bevel End (BE), Threaded (NPT/BSP), or Socketed |

| Tensile Strength | ≥ 330 MPa (for MS) |

| Yield Strength | ≥ 210 MPa (for MS) |

| Density | ~7.85 g/cm³ |

| Corrosion Resistance | Low (requires painting/coating if exposed to moisture) |

| Operating Pressure | Depends on thickness and grade, typically 5 to 30 bar |

| Temperature Range | -20°C to 400°C |

The Usage of Galvanized Iron Pipe in Iraq

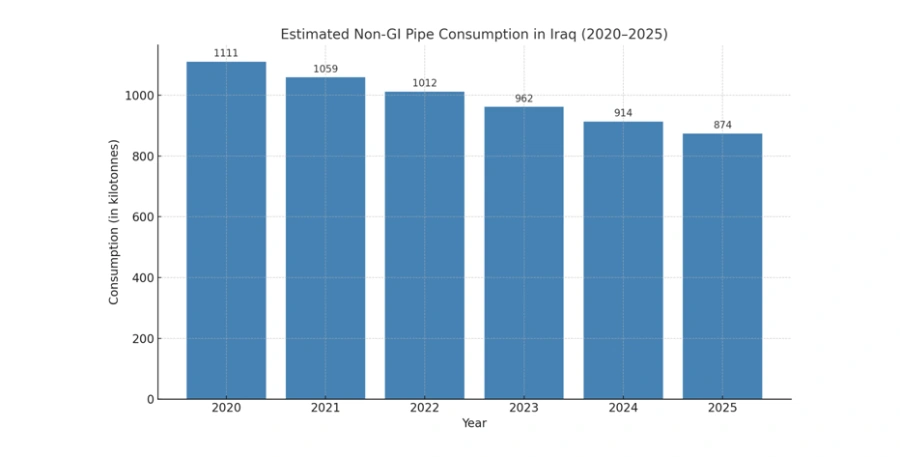

In this bar graph, we will look at the estimated figures of non-GI pipe consumption from 2020 to 2025 in Iraq.

What are the Key Features of Mild Steel Pipe and Tube?

Here are the precise key features of mild steel pipe in Mosul, Iraq, that you can buy from the Matco Industry.

- It is immensely sustainable, durable, and strong.

- It comes with a magnetic nature due to a high percentage of ferrite and iron.

- It can resist any condition for about 100 years or even more.

- It comes at reasonable prices in comparison to the other steel pipes and tubes available in the Iraqi market.

- It contains low carbon content.

- It can be readily welded.

- It comes with high tensile strength, which makes it easy to fabricate.

What are the Pros and Cons of Mild Steel Pipe and Tube?

Pros:

- It is cost-effective.

- It is easy to work in any type of industry.

- It is resistant to corrosion.

- It is strong and durable.

- It has good weldability.

Cons:

- It is prone to rusting during storage.

- It gives limited aesthetic appeal.

- It contains low thermal resistance.

- It is not suitable for potable water (uncoated).

- It is heavier than its alternatives.

Applications of MS Steel Pipes and Tubes

Here is the list of applications of steel pipe and tube in Najaf, Iraq, in different industries that every individual should know:

1. Machinery Manufacturing

Mild steel tubes are “regular guests” in the machinery manufacturing sector. They possess good toughness and cannot be easily broken, which makes them highly fit to bear mechanical loads. They are extensively employed in equipment frames, transmission components, hydraulic systems, etc.

2. Automobile Manufacturing

In the automotive field, because of its excellent weldability and convenient assembly and maintenance, mild steel tubes are primarily utilized in structural parts like frames, exhaust pipes, shock absorbers, etc., to save costs without losing strength. Such as car chassis, steering wheel shaft, anti-collision beams, mufflers, etc., all cannot be separated from it.

3. Aviation and Shipbuilding

While the aerospace industry tends to utilize lighter alloy material, ERW pipe in Baghdad, Iraq, is still used in some auxiliary structures, including ground equipment and maintenance tools. In shipbuilding, it is used for hull frames, support pipes, exhaust systems, etc., capable of withstanding impact and saving costs.

4. Fitness Equipment

When you visit the gym, you can see that many pieces of equipment are made of steel pipes, such as barbell racks, treadmill stands, and bicycle trainers. Mild steel tubes possess high strength and good bending resistance, which is highly appropriate for the intense use conditions of fitness equipment.

5. Industrial Pipes

Mild steel tubes are used to convey fluids like oil, water, and gas. They are simple to weld and can also be fashioned in various shapes and sizes according to requirements. They are a vital component of manufacturing equipment and factories, for instance, the boiler tube, steam pipeline, liquid pipeline, etc., in a chemical plant.

6. Construction Field

A lot of construction machinery, like framework support, tower cranes, scaffolding, etc., relies on the stability, durability, and strength of mild steel pipe and tube in Erbil, Iraq. Construction support frames, protective sheds, and safety guardrails at building sites are typically fabricated from mild steel tubes.

7. Agricultural Field

Mild steel tubes are also standard in agricultural machinery, such as sprinkler systems, agricultural machinery frames, livestock fences, etc. For example, the steel structure frame of the greenhouse and the conveying system of the harvester are both made of mild steel tubes, which are both light and durable.

8. Transportation Facilities

In highway building, railways, and city transport infrastructure, mild steel tubes find application in guardrails, signboard brackets, street light poles, etc. For instance, highway anti-collision guardrails, subway station handrails, and bus stop brackets all need their support.

Wrapping It Up!

We hope this blog has provided you with all the precise details about mild steel pipes and tubes. However, to fulfill your particular needs and preferences for the MS tube in Baghdad, Iraq, you should reach out to Matco Industry. We have a wide team of skilled and experienced professionals who are willing to offer assistance in selecting the right products based on your requirements, ensuring your project is completed on time.

Furthermore, we have served hundreds of clients and guided them to save on their construction or infrastructure projects by delivering premium steel pipes and tubes, fittings, valves, and more at the most competitive prices. So, what are you waiting for? Connect with us today and get your cutting-edge steel pipes and tubes according to your preferences.