Galvanized Pipes | Significant Types, Technical Configuration, Features & More

Are you looking for the best manufacturer of GI pipe in Baghdad, Iraq? If yes! Before purchasing, ensure that you have a keen understanding of galvanized iron pipe.

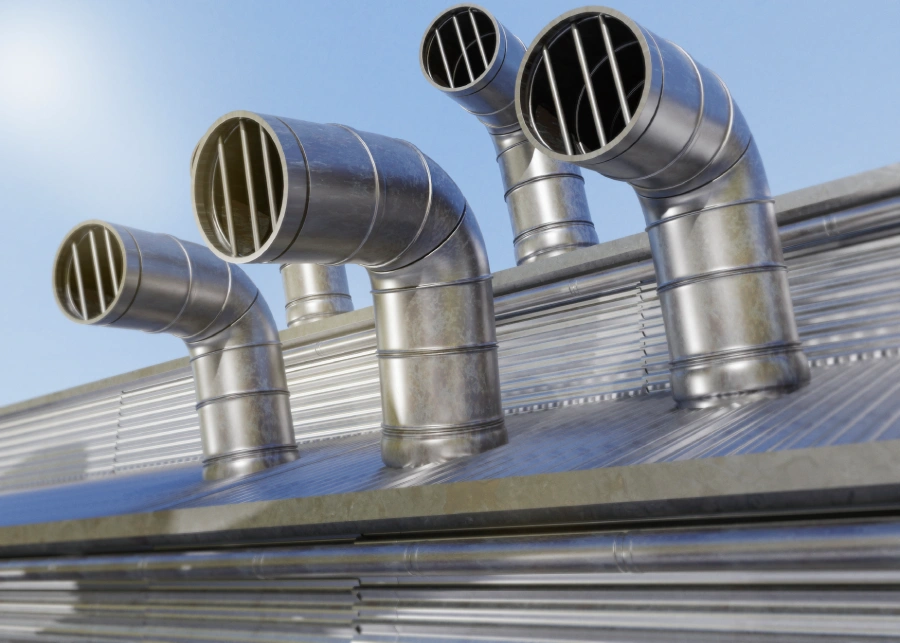

Furthermore, galvanized iron steel pipes and tubes have been rapidly growing in demand in the infrastructure sector of Iraq for quite some time, and their rising popularity is justified. Moreover, one of the most beneficial things about buying GL pipes is that they are cost-effective and have corrosion-resistant properties. Therefore, it make them an exceptional and ideal choice for the construction field. Additionally, galvanised iron pipes are widely used to supply water in multiple rural areas where the water demand is minimal. However, what are these iron pipes? This question frequently arises, especially when you are hearing about it for the first time. With its zinc coating and steel composition, galvanized pipe in Basra, Iraq, has been a reliable choice for industrial and plumbing applications.

Furthermore, its corrosion-resistant features, sustainability, and durability have made it a trustworthy choice for transporting water and other fluids. Nevertheless, it is imperative to comprehend the galvanization procedure, the composition of galvanized iron pipes, and the components that can impact their lifespan. Moreover, in this comprehensive blog, we will discuss all precise details about galvanized iron pipes, including their types, safety concerns, and more.

Technical Configuration of Galvanized Iron Pipe

| Parameter | Specification / Description |

|---|---|

| Material | Mild Steel (MS) base, hot-dip galvanized with zinc coating |

| Standard Codes | IS:1239 (Part 1) – for medium & heavy class pipes |

| Coating | Zinc coating of 40 – 120 microns (hot-dip galvanization) |

| Pipe Sizes (Nominal Bore) | 15mm (1/2″) to 150mm (6″) |

| Wall Thickness | Light: 2.0 – 2.5 mm Medium: 2.65 – 3.25 mm Heavy: 3.25 – 5.4 mm |

| Length | Standard 6 meters (custom lengths available) |

| End Connections | Plain ends / Threaded with socket / Beveled ends |

| Surface Finish | Bright or dull silver, depending on galvanizing quality |

| Tensile Strength | ≥ 300 MPa |

| Yield Strength | ≥ 195 MPa |

| Zinc Coating Adhesion | Must pass the mandrel and impact tests (as per IS standards) |

| Corrosion Resistance | High (zinc coating provides sacrificial protection) |

| Applications | Water supply, gas pipelines, fencing, structural use, fire-fighting systems |

| Pressure Rating | Varies by class: Light: ~10 kg/cm² Medium: ~25 kg/cm² Heavy: ~40 kg/cm² |

| Thread Type | BSP (British Standard Pipe) threads or NPT (on request) |

| Welding | Electric Resistance Welded (ERW) |

What are the Significant Types of Galvanized Iron Pipe?

Let’s discuss the imperative types of galvanised pipe in Mosul, Iraq, from the perspective of innovation and study why it has become more essential than standard steel pipes and tubes. It will guide you in purchasing the best GI pipes according to your needs and preferences:

1. Hot Dip Galvanized Steel (HDG)

We can deduce from its name that it will be produced using the Dipping of steel in any alloy. However, this is the correct answer because it is made by dipping Steel in Zinc alloy. First, the base metal must be cleaned manually with chemicals. Both provide a good quality bond that can be formed between the zinc coating and the steel. The benefit of this specific process is that it is considered cost-effective and can also be done quickly, even for complicated shapes. Nevertheless, the final galvanization of galvanized pipe Erbil, Iraq, is not the same as the other galvanization processes. Additionally, it is included in galvanization.

Technical Configuration

| Parameter | Specification / Range | Unit | Remarks |

|---|---|---|---|

| Base Material | Mild Steel / Carbon Steel | — | Complies with ASTM A36, IS 2062, etc. |

| Galvanization Method | Hot Dip Galvanizing | — | As per ASTM A123 / ISO 1461 |

| Zinc Coating (Thickness) | 40 – 120 | μm | Depending on exposure and |

| Zinc Coating Mass | 275 – 610 | g/m² | Higher coating for outdoor/industrial use |

| Steel Thickness Range | 1.6 – 25 | mm | Can vary based on the application |

| Tensile Strength | 250 – 550 | MPa | Varies with base steel grade |

| Yield Strength | 240 – 350 | MPa | Based on IS 2062 / ASTM A36 grades |

| Elongation | 20 – 30 | % | Minimum elongation in 50 mm gauge length |

| Hardness (Brinell) | 130 – 180 | HB | Before galvanization |

| Zinc Purity in Coating | ≥ 98.5 | % | Commercial-grade zinc |

| Adhesion of Coating | No flaking, peeling, or cracking | — | Visual inspection as per standards |

| Coating Uniformity | ± 10 | μm | Allowed variation in thickness |

| Corrosion Resistance | > 20 years (rural); 10–15 years (industrial/coastal) | — | Estimated service life |

| Standards Compliance | ASTM A123, A153, IS 4759, ISO 1461 | — | For general structural steel |

| Surface Finish | Bright / Matte grey (zinc spangle) | — | Varies by cooling and aging |

| Coating Adhesion Test | Knife Test / Impact Test | — | As per ASTM A123/A123M |

| Bending Radius (min.) | 1.5 – 3 times the thickness | — | To avoid the cracking of the zinc coating |

| Storage Guidelines | Dry, ventilated area; avoid water traps | — | To prevent white rust |

2. Electrogalvanized Steel (EG or EGI)

One of the most distinctive of these methods, detailed, electrogalvanizing, doesn’t entail immersing the material in a molten tank of zinc. Instead, in a GI pipe in Najaf, Iraq, an electric current is brought into an electrolyte solution applied to the steel, reducing the positively charged zinc ions to zinc metal, which is then plated onto the positively charged steel. Similar to pre-galvanizing, this process is typically performed at the first stage of manufacture.

Technical Configuration

| Parameter | Specification / Description |

|---|---|

| Material | Cold-rolled steel (CR) base with electroplated zinc coating |

| Zinc Coating Method | Electrolytic (electroplating) |

| Coating Thickness | Typically 5–30 g/m² per side (can vary up to 60 g/m² total) |

| Coating Weight | 10–60 g/m² total (Z10 to Z60) |

| Surface Finish | Smooth, uniform, with spangle-free appearance |

| Corrosion Resistance | Moderate (lower than Hot-Dip Galvanized Steel) |

| Thickness Range | 0.3 mm – 3.0 mm |

| Width Range | 600 mm – 1500 mm (varies by manufacturer) |

| Tensile Strength | 270–600 MPa (depending on grade) |

| Yield Strength | 140–420 MPa |

| Elongation | 10% – 40% depending on grade and processing |

| Surface Treatments | Oiled, phosphated, chromated, or non-treated |

| Weldability | Excellent |

| Paintability | Excellent (ideal for automotive and appliance industries) |

| Formability | Very good (suitable for deep drawing and press forming) |

| Applications | Automotive panels, home appliances, HVAC systems, office equipment, electronics, and furniture |

3. Galvannealed Steel

Galvannealed Steel is highly resistant to electrical corrosion and easier to weld than other types of steel. It is ideal for architectural purposes due to its high resistance, more rigid core, and strength. You can utilize it for doors, windows, and frame construction.

Technical Configuration

| Property | Specification / Description |

|---|---|

| Material | Galvannealed Steel (Carbon steel + Zinc-Iron alloy coating) |

| Coating Type | Zinc-Iron alloy (produced by annealing hot-dip galvanized steel) |

| Coating Designation (ASTM A653) | A25, A40, A60 (indicates coating weight in oz/ft² – A60 = 0.60 oz/ft² total both sides) |

| Coating Thickness | Typically 5-10 microns per side |

| Base Steel Grade | Commercial Steel (CS), Drawing Steel (DS), Structural Steel (SS), High Strength Low Alloy (HSLA) |

| Tensile Strength | 270–550 MPa (varies by grade) |

| Yield Strength | 140–340 MPa (varies by grade) |

| Elongation | 20–35% (depending on thickness and steel grade) |

| Surface Appearance | Matte gray, slightly rough texture (ideal for paint adhesion) |

| Weldability | Excellent (better than galvanized due to reduced zinc content at weld interface) |

| Paintability | Superior (thanks to the porous iron-zinc surface for better paint bonding) |

| Corrosion Resistance | Good (not as high as pure galvanized but improves with painting) |

| Formability | Good to Excellent (varies with steel grade and coating weight) |

| Common Standards | ASTM A653, JIS G 3313, EN 10346 |

| Applications | Automotive body panels, appliances, door frames, electrical cabinets, construction parts |

| Available Forms | Sheets, coils |

| Thickness Range | 0.4 mm to 3.0 mm (typical commercial range) |

| Width Range | 600 mm to 1500 mm (varies by manufacturer) |

4. Continuous Galvanizing (CGL)

The reason for a continuous galvanization line is to offer corrosion protection for steel using zinc alloy. Zinc coat thickness controls are extensive, and GI pipe in Baghdad, Iraq, is employed for numerous applications. The primary applications are building materials, automobiles, and electrical appliances. CGL of Steel Plantek has unparalleled functions that are highly rated by customers across the globe.

Technical Configuration

td>Scale Brusher

| Section | Component / Specification | Description / Details |

|---|---|---|

| Entry Section | Coil Uncoiler | Handles HR/CR steel coils, typically 5–35 tons |

| Welding Machine | Joins coil ends before continuous processing. | |

| Entry Looper | Provides storage to maintain continuous line operation during coil change | |

| Tension Leveler (Optional) | Improves the flatness of the strip | |

| Scale Brusher | Removes oxides and dirt before cleaning | |

| Alkali Cleaning Section | Removes oil and dirt via chemical washing | |

| Heat Treatment Section | Vertical/Horizontal Furnace | Annealing furnace with direct/indirect gas-fired or electric heating |

| Furnace Zones | Pre-heating, Soaking, and Cooling zones | |

| Protective Atmosphere | HNx (Hydrogen-Nitrogen mix) to prevent oxidation | |

| Strip Temperature | Up to 750–850°C (annealing range) | |

| Galvanizing Section | ||

| Zinc Pot | Contains molten zinc (usually 99.99% pure zinc) | |

| Zinc Temperature | Approx. 450–460°C | |

| Galvanizing Method | Hot-dip galvanizing, optional Alloying with Al, Ni, Mg | |

| Air Knife | Controls coating thickness using high-pressure air jets | |

| Coating Weight | Typically 40–600 $g/m^2$ (based on customer specification) | |

| Post Treatment Section | Cooling Tower / Air Cooling | Rapid cooling of the coated strip |

| Skin Pass Mill (Optional) | Improves surface finish and mechanical properties | |

| Tension Leveler (Optional) | Corrects shape and improves flatness | |

| Passivation or Chromating | Prevents white rust during storage and transport | |

| Oiling Unit | Applies a protective oil layer | |

| Exit Section | Exit Looper | Maintains continuous production during recoiling |

| Shear / Cutter | Cuts the strip at the end of the coil | |

| Recoilers | Rewinds the galvanized strip into coils | |

| Coil Car | Transfers the coil to the storage or dispatch area | |

| Production Capability | Strip Width | 600 mm – 1600 mm (varies by line) |

| Strip Thickness | 0.2 mm – 3.2 mm | |

| Line Speed | 60 – 180 m/min (can go up to 250 m/min for high-speed lines) | |

| Annual Production Capacity | 100,000 – 500,000 tons/year | |

| Control Systems | PLC + SCADA | For automated control, real-time monitoring, and diagnostics |

| Quality Monitoring | Online thickness gauge, coating weight gauge, surface inspection system |

10 Different Industries Where Galvanized Pipes are Used

Here, we have mentioned the list of galvanized pipe in Basra, Iraq, applications in different industries that every consumer should know:

- Construction Industry

- Water Supply Systems

- Agriculture and Irrigation

- Oil & Gas Industry

- Fencing & Infrastructure

- Manufacturing & Industrial Plants

- Mining Industry

- Automotive Industry

- Marine Industry

- Power & Energy Sector

Significant Features of Galvanised Iron Pipes

Before making any final decision when it comes to purchasing the best piping material for your construction or any other project, it is significant to know what makes galvanised pipe in Mosul, Iraq, a reliable choice. Furthermore, let’s discuss the key features before purchasing.

- Galvanized iron pipes are durable, sustainable, and maintain high longevity properties.

- GI pipes are one of the best suited for rigid fabrication.

- Galvanized pipes are easy to work with in forming any shapes and sizes.

- GI pipes are for their corrosion resistance characteristics.

- GI pipes are the most suitable for use in severe temperatures.

Wrapping It Up!

We hope this end-to-end blog has provided you with all the key knowledge with their standard technical configuration. However, if you are looking for a reliable manufacturer who delivers the best galvanized pipe in Erbil, Iraq, look no further than Matco Industry. We have a team of expert and skilled professionals who will provide you with high-quality GI pipes. Furthermore, we offer a wide range of customization options, so that our consumers never have to compromise when buying GI pipes for their project. So, do not wait any longer. Connect with us today and let us fulfill your GI pipe needs and requirements without worrying about exceeding your budget!